Research

Atomic Force Microscopy

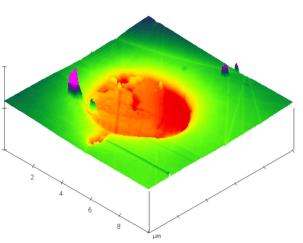

The electrochemical deposition of metals and metal oxides at the solid-electrolyte interface has fundamental as well as commercial relevance for both the metal plating and corrosion industries. With the use of imaging techniques such as atomic force microscopy (AFM) and scanning tunneling microscopy (STM) we are able to probe the electrochemical interface and accurately determine structural information directly. Electrochemical deposition takes advantage of the fact that room temperature control of the nucleation and growth modes is possible via variation of simple properties such as the applied potential.

A particular example of the benefits of these methods is templated deposition on highly ordered pyrolytic graphite (HOPG); this electrode material consists of large areas of basal plane graphite interspersed with steps, at which edge planes are exposed. The greater activity of these edges has been exploited to generate MoO2 wires having thicknesses of the order of tens of nanometres. When reduced to Mo, these wires have application in for example hydrogen sensing, and can also be used in multi-step processes; we have deposited a polymer film over the entire electrode then removed the MoO2, leaving in effect an array of carbon nanowires separated by an insulating film.

AFM imaging is also used for a wide variety of applications including the in-situ study of metal deposition processes and analysis of film properties such as roughness and thickness. The Compton Group uses a Veeco / Digital Instruments Multimode SPM equipped with a Nanoscope III controller. The system has been modified for electrochemical use with a DI fluid cell and Eco Chemie potentiostat.

The sample is mounted on a piezoelectric scanner allowing extremely precise movement in the x, y, and z directions. The sample is then rastered in the x and y directions under a sharp tip. This tip is mounted at the free end of a cantilever (as shown) upon which a laser beam is focussed. The beam is reflected from the back of the cantilever to a set of four photosensitive diodes. These detect the deflection of the laser beam arising from the cantilever moving as the sample is rastered. In contact mode, a feedback loop moves the piezo in the z direction, maintaining the laser beam at a constant deflection. In this way the sample is scanned with a constant force and the resulting z piezo motion produces a topographical map of the region scanned with a vertical resolution smaller than 100pm in favourable cases. The AFM can be used in air, or under liquids.

The Compton Group has undertaken a variety of ex-situ applications (deposition of polydivinylbenzene films, microelectrode characterization, analysis of lead dioxide morphology, analysis of nucleus distribution, overgrowth, organic crystals and the effect of ultrasound on surfaces) and in-situ applications (deposition of lead on boron-doped diamond electrodes, oxidation of gold electrodes and dissolution of calcite).